We supply Trawl Warps the following is a sample of Types and Sizes.

- Rubber Covered Wire Bridles and Sweeps

- Wire Pennants

- Combination Wire Bridles

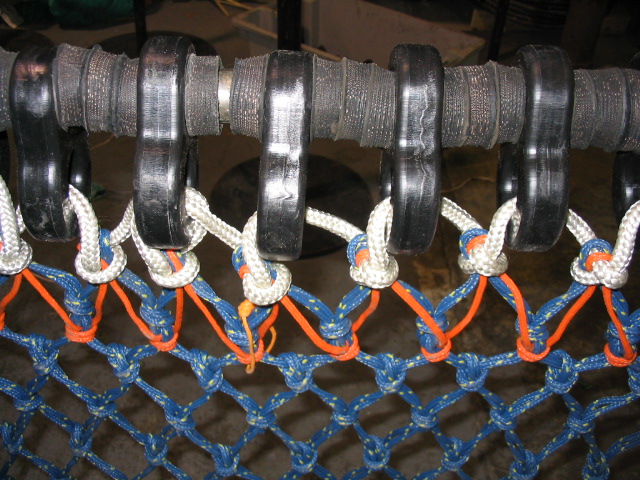

- and custom made Bolch Lines manufactured using plastic “Snowmen”

Plastic "Snowmen"

Bolshline on Groundfish Trawl

We have an ESCO 500 Ton Wire Press and carry a range of Dies, Ferrules, Thimbles. Tube Thimbles and Terminal Ends.

Wire Rope Information

- 6-Strand Combination Rope + IRWC

- Right regular lay - performed

- Steel wire strands covered with PP split film.

- Blue with white marking yarns in one strand

Minimum tensile strength of wire

Galvanized 160 kp/mm2 = 1570 N/mm2

|

Code Number |

Diameter mm |

Strand Construction |

Steel Area mm2 |

Approx. Weight kg/m |

Min breaking load KP |

|

T06 0080 601A |

8 |

6 x 6 x 0.40 |

7.9 |

0.09 |

1600 |

|

T06 0100 601A |

10 |

6 x 6 x 0.50 |

13.0 |

0.15 |

2600 |

|

T07 0120 601A |

12 |

6 x 7 x 0.52 |

15.8 |

0.19 |

3100 |

|

T08 0140 601A |

14 |

6 x 8 x 0.60 |

23.8 |

0.28 |

4650 |

|

T08 0160 601A |

16 |

6 x 8 x 0.70 |

32.4 |

0.37 |

6200 |

|

T08 0180 601A |

18 |

6 x 8 x 0.80 |

40.3 |

0.46 |

7400 |

|

T08 0200 601A |

20 |

6 x 8 x 0.90 |

51.6 |

0.58 |

9700 |

|

T08 0220 601A |

22 |

6 x 8 x 1.10 |

81.9 |

0.87 |

14200 |

|

T08 0240 601A |

24 |

6 x 8 x 1.20 |

99.4 |

1.04 |

17100 |

|

T08 0260 601A |

26 |

6 x 8 x 1.30 |

110.2 |

1.17 |

19000 |

|

T08 0280 601A |

28 |

6 x 8 x 1.40 |

125.4 |

1.33 |

21600 |

|

T08 0300 601A |

30 |

6 x 8 x 1.50 |

146.3 |

1.54 |

25000 |

|

T08 0320 601A |

32 |

6 x 8 x 1.60 |

171.5 |

1.78 |

29200 |

How to Order

It is important to describe the steel wire rope accurately as possible. A correct order should contain the following information:

- Diameter

- Construction

- Direction of lay

- Type of lay

- Core

- Wire tensile strength

- Surface protection of wire (galvanized/ungalvanized)

- Type of lubricant

- Length

- Quantity

- Processing of steel wire rope ends (end fittings)

- Packaging ( coil, crosses, reels, etc)

If you have any questions on the type of steel wire rope to be used, contact us at the above number and we will do our best to assist you.

Running in Steel Wire Rope

After the steel wire rope has been installed, we recommend that it is run through the system several times at low speed and moderate loading (e.g. 5% of tensile strength). In this way the steel wire rope will gradually become accustomed to the new conditions. The strands will settle, the steel wire rope will lengthen and the diameter will decrease a little due to the fact that the strands and the core are compressed. The steel wire rope will thus be less susceptible to damage when maximum load is applied. The time spent "running-in" the steel wire rope will be earned many time over, as the steel wire rope will thus have a longer life expectancy.

Maintenance of Guidance Equipment

Thorough maintenance of the equipment that the steel wire rope will come into contact with is of great significance for the steel wire rope's life expectancy. Worn sheaf grooves, guide rolls, etc., crooked sheaves and jammed bearings all result in such effects as shock load and vibrations in the steel wire rope, which have a destructive effect on the steel wire rope, resulting in exaggerated wear and tear and fatigue.

Equipment that the steel wire rope comes into contact with must be inspected regularly. If there is a problem with the equipment, it must be replaced or repaired immediately. If the guidance equipment is repaired by welding, care should be taken to ensure that hardness of the welding material is approx. 300 Brinel, so that it is the sheaf that is worn, and not the steel wire rope.

Maintenance of Steel Wire Rope

The oil/grease that is added to the steel wire rope during production is only sufficient to protect the steel wire rope during the storage period and initial use. The steel wire rope must be lubricated regularly.

Thorough lubrication is extremely important for the steel wire rope's life expectancy, as the purpose of lubrication is partly to protect the steel wire rope against rust, and partly to reduce friction between the wires and the strands in the steel wire rope. Friction is also thereby reduced between the steel wire rope and the surfaces with which it comes into contact.

The lubricant used must be free of acids and must not have a destructive effect on the steel wires, the fibre core and/or the environment. The lubricant must have a consistency that enables it to penetrate the core and the strands. The steel wire rope must be cleaned before lubrication.

To achieve maximum lubrication effect, the lubricant should be applied during operation, at a sheaf or on the drum, as this is where the steel wire rope opens up and makes it easier for the lubricant to penetrate.A special lubricating oil, WIRE OIL Type 01, which satisfies the special requirements for lubrication of steel wire ropes. The oil has excellent penetrative and lubrication qualities. It is also water-resistant and contains additives that dissolve rust and prevent further formation of rust during storage and operation. The oil is easily applied with a brush

Inspection of Steel Wire Rope

The following guidelines cover possible points that should be checked in conjunction with the inspection of steel wire rope. This is not a complete manual, nor is it an alternative to the relevant norms and standards.

Wear and Tear

As a rule, a steel wire rope should be replaced when the outer wires are worn down to 1/3 of the original wire dimension.

Elongation

All steel wire ropes become elongated when loaded. The elongation of a steel wire rope during its lifetime can be divided into three phases:

Phase 1: The new steel wire rope becomes longer quite naturally during its initial period of use. This partly because of the loading, and partly because the steel wire rope settles.

Phase 2: When the steel wire rope has settled. For most of its lifetime, the steel wire rope does not become much longer. Elongation during this phase is mainly due to wear.

Phase 3: The steel wire rope suddenly becomes longer very quickly. This means that the steel wire rope is deteriorating rapidly due to such causes as advanced wear and fatigue. The steel wire rope must be replaced immediately.

Reduction of Dimensions

Every noticeable reduction of the steel wire rope's dimension in comparison with its original dimension indicates a deterioration in the steel wire rope. The reduction may be due to such causes as:

- External/internal wear and tear.

- Compression of strands and/or core.

- External/internal formation of rust.

- Elongation.

Rust

Rust is just as important a factor as wear and tear in terms of evaluating the steel wire rope's condition. Rust is normally caused by poor maintenance of the steel wire rope and promotes quicker fatigue in the wires (fragility/creation of cracks).

Kinks

Kinks cause permanent damage to the steel wire rope. Kinks are formed due to extraction of loops.

The steel wire rope must be replaced immediately

Bird's Nest

A "bird's nest" (the strands rising in the same place) is created by such actions as the steel wire rope being subjected to torsion (rotated), sudden unloading, running through sheaf grooves that are too small and/or winding on a drum that is too small

If you are in any doubt as to whether the steel wire rope should be scrapped or not, please contact your local salesman or our Technical Department as soon as possible.

Local Wear and Tear/Damage

Local wear and tear is most often caused by poor winding. All fittings and splicing must also be inspected for wear or broken wires, loose or split strands, wear or cracks in fittings, etc.

Fire Damage

After a fire or exposure to high temperatures, metal damage, loss of oil/grease and destruction of fibre core, etc., may occur. The steel wire rope must be replaced immediately.

Core Protruding Between Stands

Regardless of the cause the rope must be replaced immediately.